UNLEASH THE POWER OF YOUR ORGANIZATION'S DATA

Unleash the power of your organization’s data

OT issues

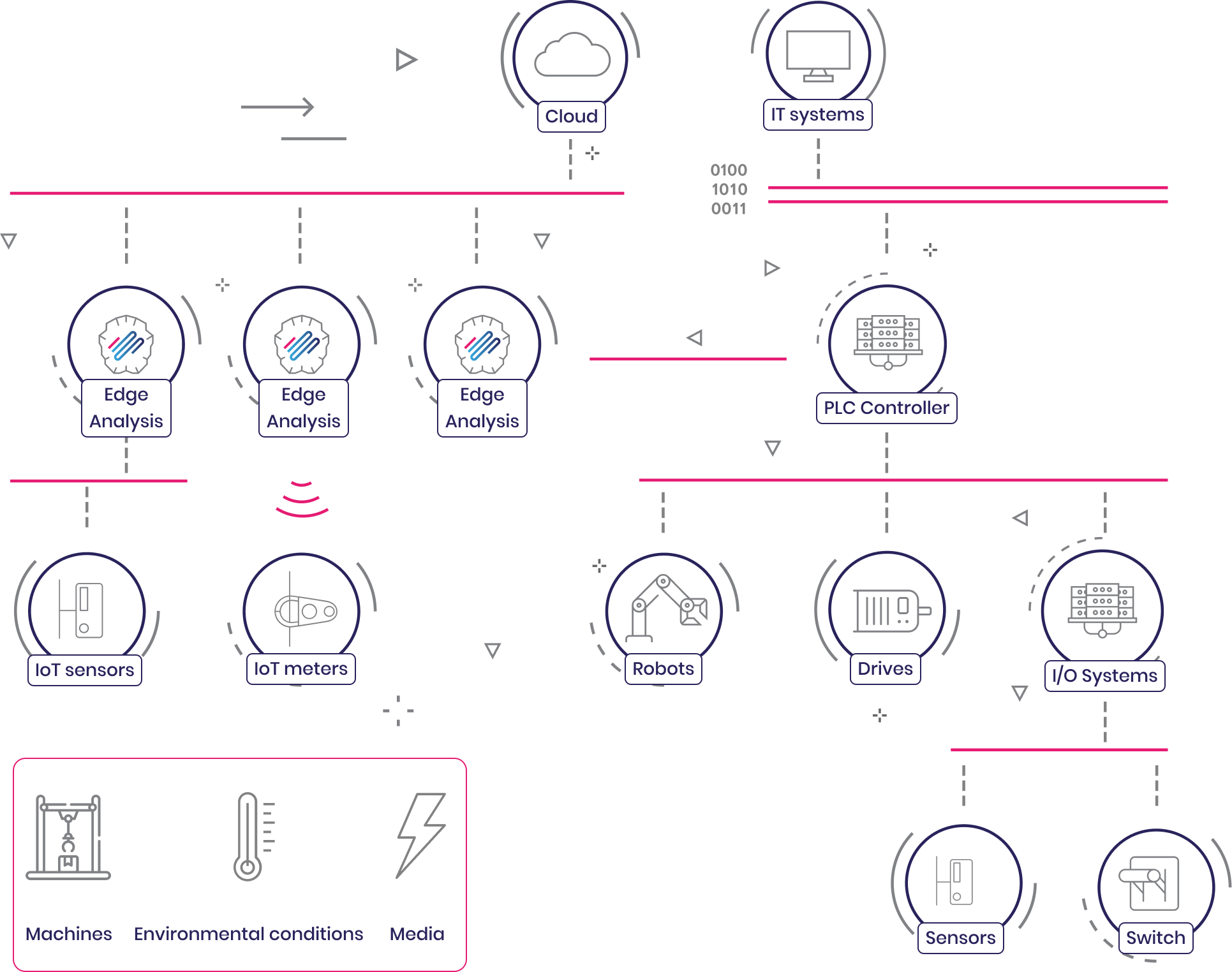

Technology in NAZCA 4.0

OT issues

Edge computing

The solution consists of the acquisition, processing and pre-analysis of data at the end of the production line, i.e. near the production site.

The need to pre-process data near its creation arises from the fact that IIoT devices collect large amounts of data that need to be processed in real time and transferred to the cloud layer.

Edge computing in NAZCA 4.0

Integration of existing infrastructures

In most cases, it is possible to obtain data from the existing infrastructure without the need to expand the measuring systems or change the control system. Machines, robots or PLCs allow access to diagnostic data or control parameters via correspondingly configured communication protocols (OPC, Modbus, MQTT).

Without highlighting the potential of Industry 4.0, machines are a series of disconnected components that act as information silos ( at the same time limit the proper management of machinery, logistics, sales and production planning).

See your data in action!

Leave your e-mail. We will contact you and show you NAZCA 4.0 in action.

Zobacz więcej co może Ci zaoferować NAZCA.

Wejdź i się przekonaj jak wdrożenie NAZCA 4.0 wspiera działanie firmy.

IT issues

IT issues

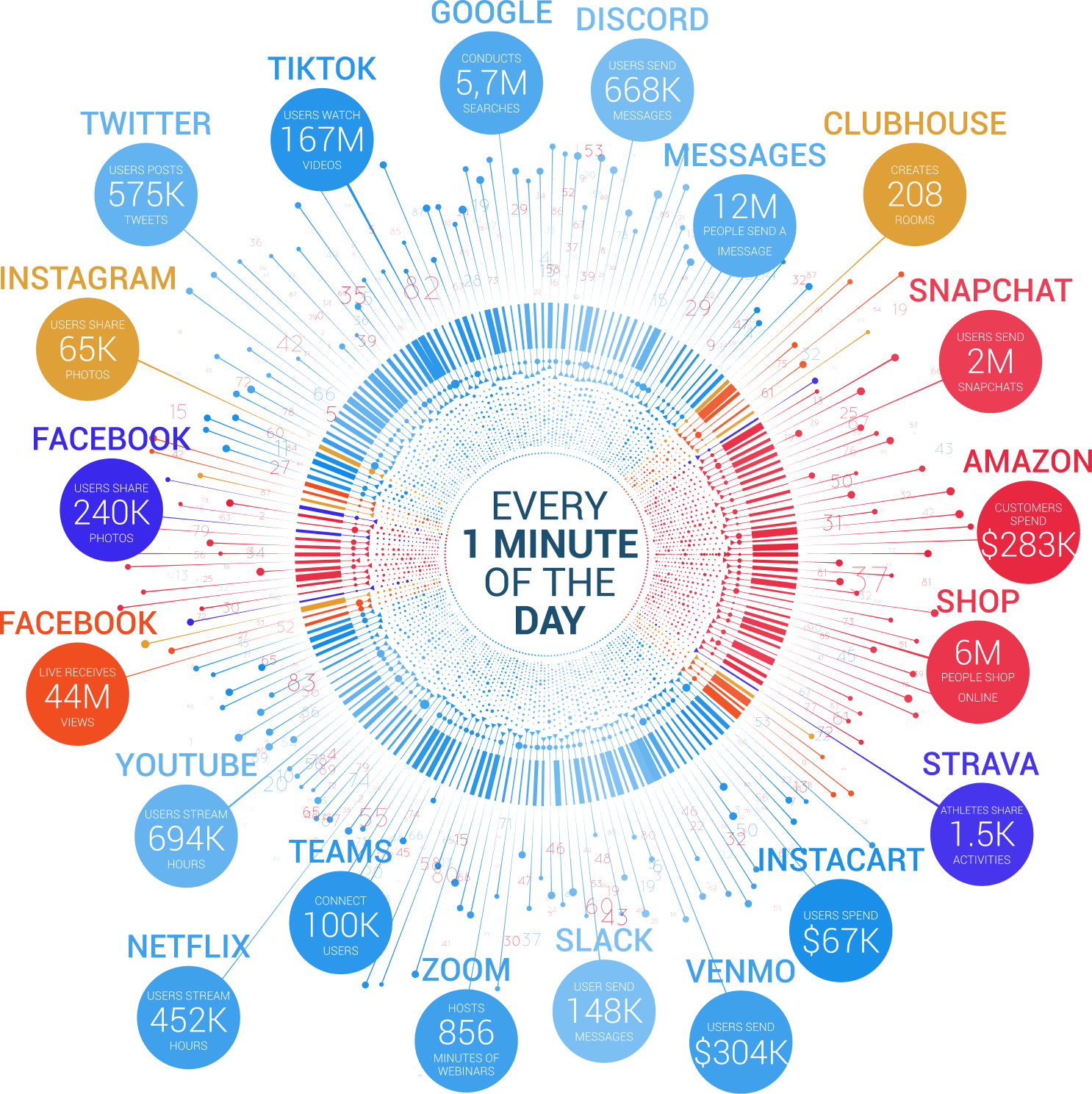

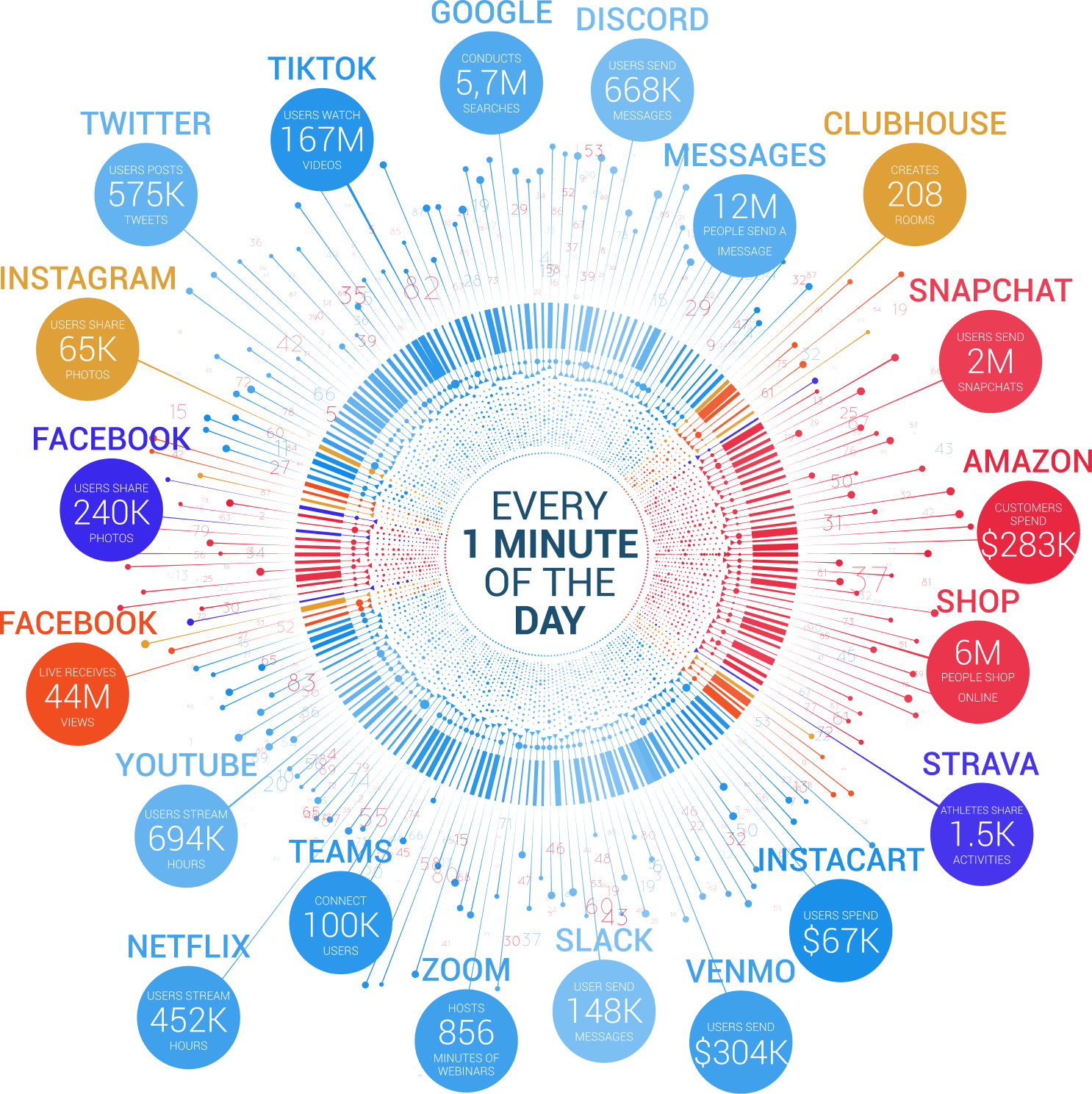

BigData in use

When we talk about big data, we mean very large amounts of data. We generate them through many daily routine activities, by using apps or by visiting websites. This large amount of data cannot be processed by a single person or a classic analysis tool.

Private companies, public administrations, social networks, mobile applications and research institutes are implementing big data projects to automate the collection and processing of large amounts of data.

The main features of BigData:

- Volume – large volume

- Velocity – Processing speed

- Variety – Variety of formats and data types

- Veracity – Reliability and Accuracy

- Value – Value for decision-making processes

BigData in use

When we talk about big data, we mean very large amounts of data. We generate them through many daily routine activities, by using apps or by visiting websites. This large amount of data cannot be processed by a single person or a classic analysis tool.

Private companies, public administrations, social networks, mobile applications and research institutes are implementing big data projects to automate the collection and processing of large amounts of data.

The main features of BigData:

- Volume – large volume

- Velocity – Processing speed

- Variety – Variety of formats and data types

- Veracity – Reliability and Accuracy

- Value – Value for decision-making processes

Batch analysis

Includes performing computations with large amounts of data according to a predetermined schedule.

Examples of such calculations:

- Calculation of production indicators (OEE, CPK, MTTF…) after each change

- Identification of trends and statistical data flows of variables

- Estimation of machine health on the basis of the last working day

- Updating the neural network (Instructions)

- Export/Import of data from the external system

- Preparation of data for the BI report

In the context of NAZCA 4. 0, these tasks can be solved with the following tools:

Spark – by preparing a task for this system

NiFi – Use of additional processors prepared by APA

You can create your own Python functions and use the included SDK

In the context of NAZCA 4.0, these tasks can be solved with the following tools:

Spark – by preparing a task for this system

NiFi – Use of additional processors prepared by APA

You can create your own Python functions and use the included SDK

Stream analysis

Batch analysis involves performing calculations with data that are continuously transmitted. These are e.g. data streams containing the current measured values transmitted by the measuring devices.

Examples of applications of streaming analysis:

- Current calculation of aggregates in so-called “windows” – e.g. counting of moving averages

- Reduction of the measurement quantity by e.g. averaging

- Real-time event detection and instant response

- Search for anomalies in the operation of devices

- Data transmission to external systems

- Enrichment of data with additional information prior to storage

- Filter, change units

- Sorting events by their time of occurrence

In the context of NAZCA 4.0, these tasks can be solved with the following tools:

Flink – by preparing a task for this system

NiFi – Use of additional processors prepared by APA

AI issues

Advantages of BIG DATA

Scalability

Safety

Integration

Modularity, containerization

![]()

Scalability

A solution that grows with your business or your requirements, the ability to add more machines, prototyping and deployment with a single system.

![]()

Safety

Data access security, data storage (redundancy).

![]()

Integration

Discussion of the possibilities of communication with the world.

![]()

Modularity, containerization

Overview of containerization and what there is, the ability to work on-premis, cloud, hybrid. Cloud agnostic.

Scalability

Safety

Integration

Modularity, containerization

![]()

Scalability

A solution that grows with your business or your requirements, the ability to add more machines, prototyping and deployment with a single system.

![]()

Safety

Data access security, data storage (redundancy).

![]()

Integration

Discussion of the possibilities of communication with the world.

![]()

Modularity, containerization

Overview of containerization and what there is, the ability to work on-premis, cloud, hybrid. Cloud agnostic.

See your data in action!

Leave your e-mail. We will contact you and show you NAZCA 4.0 in action.

AI issues

Artificial intelligence in use

What we use for

At NAZCA 4.0 we develop AI solutions that are simple, intuitive and understandable for the end customer. Our algorithms are used to:

Evaluation of the quality of the final product so that the defective element can be corrected or discarded as early as possible in the initial phase

Classification of the final product, classification of the quality of the machine operation

Classification of the final product, classification of the quality of the machine operation

A single tool

AI for optimizing production processes

One of the most important applications of AI methods is optimization. Thanks to the aggregation and archiving of data from plants and processes, appropriately designed algorithms can suggest the optimization of individual parts of the production process, resulting in a reduction in the consumption of media such as electricity, compressed air, etc.

Directional areas

Field of electro-energy data

Vibration data range

Compressed air data field

![]()

Field of electro-energy data

Artificial intelligence constantly monitors the parameters of the electrical signals so that it is able to inform the user of any irregularities that have occurred or will occur in the near future. By learning everyday habits, appropriate algorithms protect the power consumption in order to avoid or minimize exceedances of the ordered power. Continuous analysis of the electrical signals makes it possible to measure the quality of the signal and to monitor the reactive power, which damages machines and causes additional costs in the form of fines.

![]()

Vibration data range

Every machine vibrates according to the laws of mechanics. Vibrations often provide information about potential damage to machine components. Therefore, appropriate monitoring is advisable to estimate the time of damage and to continuously monitor machine conditioning. The Nazca4.0 platform is equipped with algorithms that continuously monitor vibrations and determine the condition of the device taking into account the vibration standard.

![]()

Compressed air data field

Field of electro-energy data

Vibration data range

Compressed air data field

![]()

Field of electro-energy data

Artificial intelligence constantly monitors the parameters of the electrical signals so that it is able to inform the user of any irregularities that have occurred or will occur in the near future. By learning everyday habits, appropriate algorithms protect the power consumption in order to avoid or minimize exceedances of the ordered power. Continuous analysis of the electrical signals makes it possible to measure the quality of the signal and to monitor the reactive power, which damages machines and causes additional costs in the form of fines.

![]()

Vibration data range

Every machine vibrates according to the laws of mechanics. Vibrations often provide information about potential damage to machine components. Therefore, appropriate monitoring is advisable to estimate the time of damage and to continuously monitor machine conditioning. The Nazca4.0 platform is equipped with algorithms that continuously monitor vibrations and determine the condition of the device taking into account the vibration standard.

![]()

Compressed air data field

See your data in action!

Leave your e-mail. We will contact you and show you NAZCA 4.0 in action.