Author:

Artur Pollak, CEO APA Group

Will artificial intelligence penetrate the factories permanently? Or is it just another technical innovation whose implementation will not change the character of the entire industry? We are investigating how this technology already affects production processes today.

Artificial Intelligence (AI) is a technology based on machines capable of performing tasks previously performed only by humans. It combines data (which is getting simpler and more numerous), algorithms and computing power.

The term “artificial intelligence” was proposed by the American computer scientist John McCarthy, for whom it was the science and technology of designing intelligent machines.

How does it work?

Algorithms that analyse device and machine data can provide early warning of possible irregularities and also predict what will happen in the near future. In this way, faults and damages of all kinds can be detected automatically without disassembling the machine. Processing data on the condition of raw materials and products enables better management of supply chains.

In addition, production and logistics costs can be modelled. In security systems, AI can analyse movements and events recorded on the cameras. All these and other functions are possible with machine learning algorithms. The machine receives the data and then searches for certain patterns. He then “decides” whether he should take concrete measures.

For this reason, the information collected can easily be converted into knowledge and practical application. However, deep learning, which already has a lot to do with the functioning of the human brain, is the most advanced. The computer then learns to perform natural tasks for humans, such as identifying images or making predictions. This technology takes the company’s communication with the corporate environment to a whole new level.

In this context, virtual simulations with artificial intelligence should also be mentioned. It turns out that it is already possible to replace physica models and systems with digital twins that behave in the same way as “real” counterparts. This saves test costs and increases process efficiency.

What can AI do in industry?

In industrial applications, AI offers the opportunity to develop innovative products and services and to improve production. There is even a whole area of Industrial Artificial Intelligence that focuses exclusively on AI in industry.

What opportunities does this technology offer in the context of industry?

Process optimization The ideal that most AI-oriented companies strive for is to optimize the production process itself and the only job of the human being is to ensure that it runs smoothly. Algorithms make it possible to analyse ongoing processes and identify bottlenecks, i. e. areas where unnecessary, inefficient activities are carried out. Not only log data (e. g. confirmation of receipt of goods or commissioning of the machine) are collected, but also information that is particularly sensitive to the costs incurred. In the APA, for example, we see the potential of artificial intelligence to optimize energy consumption.

Efficient response to anomalies

Machine learning gives the system the “ability” to identify those internal and external factors that influence the operation of the machines. The automatic scaling of the device parameters and their predictive maintenance mean significant cost savings. Maintenance costs are reduced and downtime is minimised. Betting that bets on machine learning receive precise and automatic detection of anomalies. In this way, better quality control solutions can be created and maintenance can be managed more efficiently.

Predicting demand

Artificial intelligence allows better planning of the entire production process, particularly in terms of expected demand, seasonal mood, employment volatility, planned sales and returns. Lean supply chains and production volumes are in many cases an almost ready recipe for success.

Improving qualitative indicators

AI technology interprets performance data in conjunction with other qualitative information, such as customer feedback. In this way, you can introduce new quality products that are free from mistakes and mistakes of the previous generation.

Robotisation

For some years now, companies have been relying on the robotisation of workplaces that do without human minds and hands. What about artificial intelligence? It offers new possibilities when it comes to the development of autonomous robot devices.

In the latest models, robots are able to distinguish objects independently from each other and make autonomous, albeit undemanding decisions, e.g. when assigning goods to specific categories.

Response to Industry 4.0

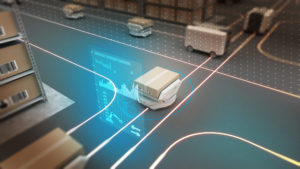

The Fourth Industrial Revolution permanently replaced the mechanical, electric and digital approach. Today, production machines are almost inextricably linked to the virtual world and IT systems, and technologies such as the Internet of Things have become a new basis for many activities. Among experts, there is even a new acronym, AIoT (Artificial Intelligence of Things), which denotes artificial intelligence of things, i.e. interconnected systems with decision-making capabilities.

Physical objects connected to the network via sensors and detectors can transmit information to each other and collect data. It is also possible to synchronize multiple data in real time. This gives people even better and more precise control over the delivered values.

Modern technologies that support Industry 4.0 are improving processes to the point where the next step is to empower intelligent machines to make decisions at a much more advanced level than before. It may be that it will soon no longer be necessary to get people to respond to lows and failures, as most of these anomalies are automatically eliminated. The individual components of the machinery are easily able to take measures themselves.

The Future of Industrial Artificial Intelligence

There are strong indications that AIoT will revolutionize the industry that was the standard for many people until recently. According to Gartner studies, more than 80% of IoT business projects will use artificial intelligence by 2022.

In comparison, this figure was still in 2019. . . Ten percent. This is a big leap, but not a miracle, because after all, the implementation of AI is almost a direct consequence of the use of the Internet of Things in industry.